Description

TURNING ANY TEMPERATURE INTO FREEZING COLD WINTER!

Stage 2 Package upgrade is the ultimate cooling upgrade and will include all parts needed to take your vehicle to subzero coolant temps. The Stage 1 kit is a great upgrade alone, eliminating heat soak unlike anything on the market. The Stage 2 kit however gets your coolant to the lowest temperature chemically possible in any condition.

For example if stock, the air going into the supercharger is 100 degrees, the Stage 1 will lower that temperature to 30 degrees, and Stage 2 will lower that further to -14 degrees.

- Race Track Safe

- Improves fuel consumption

- No condensation leaks

- Gain back ignition timing

- Below ambient intake air temps

- Stealthy Installation

- No performance loss of cabin AC

- Patent Pending Design

- Dyno and race track proven HP gains

- Entire System Warranty

- Protects engine from pre ignition

- Great Customer Support

- We provide full customer/technical support to all installations, we are only a phone call or email away

- The Interchiller system includes every nut and bolt you will require we even include highly detailed step by step photo and Video instructions.

Yes this is condensation that has turned into ice on the intercooler fluid lines of a Magnuson Heartbeat supercharger.

WHAT IS A FORCED INDUCTION INTERCHILLER?

In simple terms we are T-piecing into the cars AC system and splitting the refrigerant 50/50 between your cabin and chiller. We also install a solenoid on to the line going to the cabin so you have 2 modes of operation:

- Cabin and chiller

- Chiller only (Race mode)

Race mode is race track safe as no condensation will leak from the cars cabin evaporator.

Our interchiller core is a patented design, one of the many reasons we are able to get so cold and also have ZERO impact on cabin AC performance.

Once your intercooler fluid passes through the chiller is is supercooled to below freezing temperatures which then lowers your intake temps of your water to air intercooler system of a supercharger or turbocharger.

Our interchiller can be fitted to any car or truck as long as the car has a water to air intercooler system (supercharger or turbo charger) and an AC system. It also has no limitation to HP, it can deal with it, so far the biggest build we have been involved with has made 2400HP.

We are able to hot lap the cars at the track back to back with the same consistency every run, by the time you collect your time slip you are back to your minimum intake air temp and ready to go again.

Universal Kits

With our universal kits we are able to install the interchiller on any make and model car as long as the car has AC and water to air intercooling.We have installed universal kits on many makes and models. And almost all current bolt on kits were once universal kits.

C6 Corvette with a universal kit

AMG C63 with a universal kit

Audi RS6 with a universal kit

VT-VZ Holdens with universal kits.

Toyota MR2 with a universal kit

Monaro/Pontiac GTO with universal kits.

Toyota 86 universal kit

Chrysler 300c universal kit

Mustang with a universal kit

SRT Jeep with a universal kit

Drag Racing

The interchiller is especially useful in drag racing, typically you would perform your burnout and then stage your car, in these circumstances your intake temps are now very high and are only going to get higher as the car has no air flow for cooling, it’s at this point the chiller changes everything. It is not uncommon to have an intake temp after your burnout of 10c (50f) or less on a 30c (86f) day. We have crossed the finish line with intake temps in the low 40’s c (100f) compared to normally crossing at 80-90c (176-194f) on the LSA blower this is a lot of HP being gained!

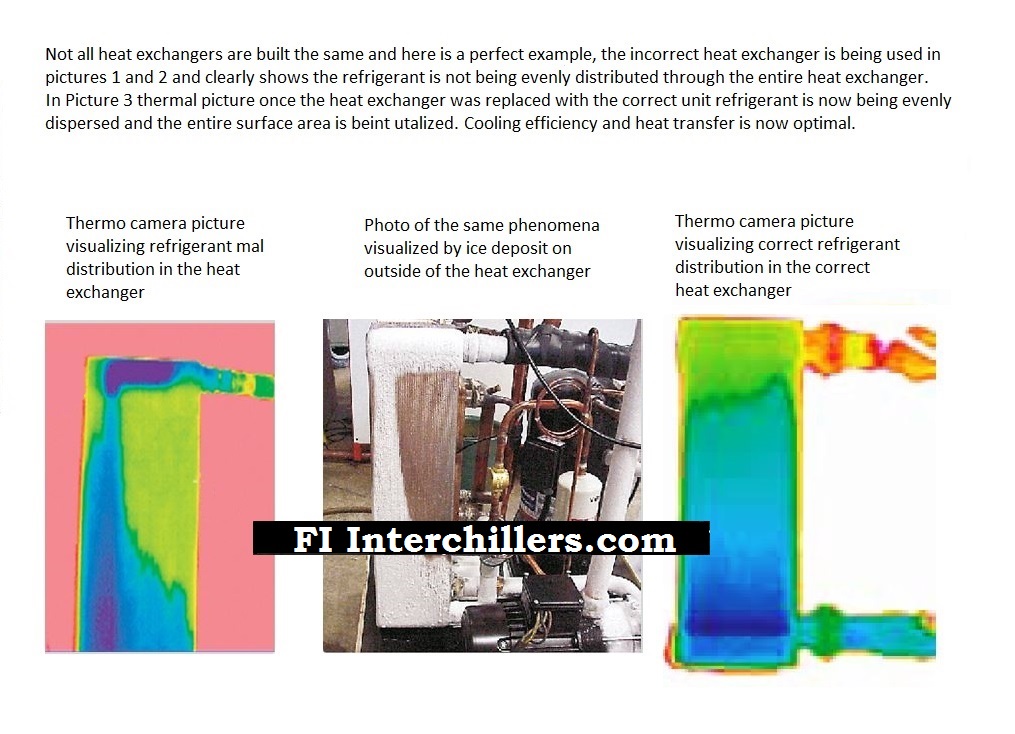

Patented Design

In Australia we are required by law to be licensed in HVAC to build our systems and handle refrigerant, for this reason we are highly skilled in a our trade. We have completed a lot of R&D into our chiller design to get an even distribution of the AC refrigerant across all of the plates in the chiller, this is essential to the cooling performance. What happens is the refrigerant shoots into the chiller at a high pressure and hits the base of the chiller, then some of the refrigerant will revert backwards and only pass over the bottom few plates, this will not utilize the entire surface area of the chiller. So we have designed a specialized distribution device in the inlet of the chiller which forces the AC refrigerant evenly across all of the plates. This results in the best heat transfer possible resulting in colder temps and getting colder temps faster. Late 2018 we were granted a patent for our design.

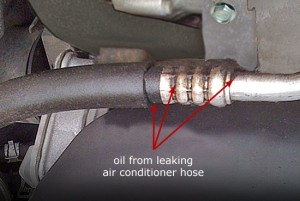

Hoses And Fittings

We refuse to use cheap and nasty AC fittings, they have built is issues along with long and short term problems. The hoses and fittings that we use are tested to SAE J2064 standards, and they actually exceed those standards. The burst pressure on them is 2500psi, this is impossible for your AC system to achieve, thus it will never burst.

We refuse to use cheap and nasty AC fittings, they have built is issues along with long and short term problems. The hoses and fittings that we use are tested to SAE J2064 standards, and they actually exceed those standards. The burst pressure on them is 2500psi, this is impossible for your AC system to achieve, thus it will never burst.

As shown in the picture below, with regular crimp style hoses they are often plagued with the issue of trapping air and PAG oil in the crimp, which over time turns acidic

With the clamp system we use this never happens and you actually have a much stronger bite of the hose into the bite sections of the fittings, for a system that will last many years to come.

The fittings we use have a tensile strength on the weakest part (the radius) of 1600kg/3527lbs

The manufacturer we buy the hoses and fittings from warranties them as long as we use their hoses, clamps and fittings. As such we warranty the entire system, this shows how confident they are in their product that it will not fail and should it fail which is highly unlikely it will be replaced.

During SAE J2064 testing of the hose/fittings when it fails the part that fails is the actual hose bursting open at 2500psi ! The fittings and clamps remain intact still holding the hose to the fitting…only the hose is bursting open. This shows how strong the clamping system is and the bite force being applied to the hose/fitting. This is much stronger than regular crimping which is why the manufacturer is able to warranty their product.

Its a case of buying the best possible AC hose/fittings that is the most versatile, flexible to out needs and of a very high quality.

CNC Fittings

All of our fittings are custom made on our CNC to look and function with an OEM standard. They are pressure tested before being sent out, so they will not leak when installed correctly.

Competition Solenoid

The comp solenoid allows you to run the AC system in 2 modes:

1. Cabin and Chiller

2. Chiller only (race track safe)

In chiller only mode you are able to get colder intake temps and you will pass tech inspection at your race track as condensation is then unable to form on the cabin evaporator and you are then allowed to use the AC system on the track, as long as your intercooler lines are also insulated to not drip condensation.

The solenoid is controlled by a simple ON/OFF switch inside the cabin.

HX Bypass Valve

In 99.99% of installs the customer is looking for all out drag racing, street racing and daily driving performance, so the front mount heat exchanger is deleted and replaced with the chiller and a reservoir. However should you wish to circuit race your car you may wish to retain your factory heat exchanger. For this we can supply a 4 port bypass valve which will give you ON/OFF control of when you use your heat exchanger. In most cases we recommend you simply delete the heat exchanger and don’t bother with the bypass valve. The reason for deleting the heat exchanger is simple, the intercooler fluid is so freezing cold that the front heat exchanger is no longer a cooling aid, it will actually heat up the intercooler fluid.

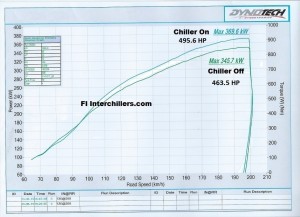

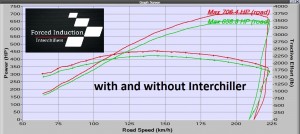

Dyno Testing

The results we have seen are amazing, the amount of HP being lost due to excessive heat is gained back and then some extra HP on top of that!

We recently tested our Interchiller in 36c (97F) summer temperatures

With the chiller only (competition mode) our IAT was at 10c (50F)

With the chiller and cabin AC running our IAT was at 15c (59F)

The cabin AC was unaffected and very nice and cold even on such a hot day. On colder days we have seen IAT temperatures range from minus -4c to 5c (24F to 41F)

A standard car without any Interchiller, the IAT is normally 10c above the ambient temperature, so when we are achieving an IAT of 10c (50F) on a 36c (97F) summer day this is equivalent to driving in winter time when the ambient temperature is 0c (32F) ice cold.

You can view the video with these results on our videos page.

On a standard 2014 model HSV Gen- F GTS fitted with the standard 6.2L LSA Supercharged engine we saw a gain of 23.9rwkw 32.1rwhp. The gain in HP is possible because of 2 reasons.

The first being the air is colder the oxygen is denser and you are getting a better cleaner burn of your air/fuel mixture. The second reason is more interesting because your intake ait temps is lower, the cars ECU is not pulling out as much ignition timing as it would have if you were at a hotter temperature. On this particular dyno run we saw a gain of 6 degrees of ignition timing…that’s a lot of power made there. Remember this is on a stock car, when you make even more heat when you over spin the blower, the gain will be even higher as you remove much larger amounts of heat.

On our shop car, the same car as above the 2014 HSV Gen-F GTS once modified with heads, cam and 16psi boost out of the LSA engine on pump fuel we saw a gain of 35.5rwkw 47.6rwhp.

On our shop car, the same car as above the 2014 HSV Gen-F GTS once modified with heads, cam and 16psi boost out of the LSA engine on pump fuel we saw a gain of 35.5rwkw 47.6rwhp.

Warranty

Our system does not cut into the cars AC system or intercooler system in any way you can easily return the car to stock and nobody would even know you had it installed.